Municipal/Industrial Plants

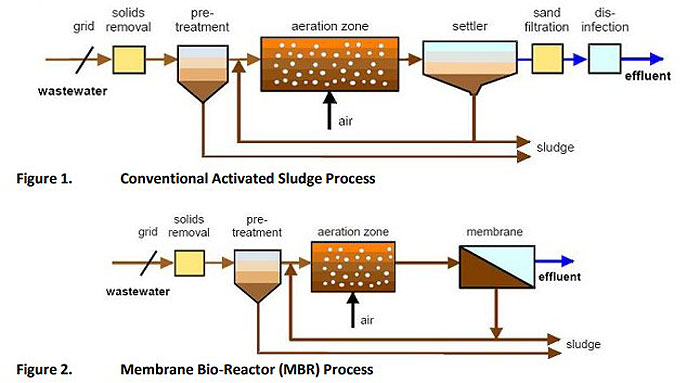

Municipal-capacity wastewater treatment plants are design/builds that typically handle 1MM – 30MM gals./day. The predominant metabolic wastewater treatment method in the U.S. is the Activated Sludge (“AS”) process.

Our GPBG municipal plants incorporate all the major features of our packaged or modular systems, and achieve equivalent system efficiency and operational benefits:

- A single tank for both aerobic and anaerobic treatment, saving space, settling time, and batch transfers. [Existing wastewater treatment systems can be refitted in the same footprint and achieve all the efficiency improvements noted.]

- Standard SCADA system for plant monitoring and control.

- One Moving Moving Part Technology which minimizes mechanical maintenance and cost, and creates superior oxygenation for better digestion.

- A membrane bioreactor in a low pressure environment with regular, gentle backwashing for the greatest filtration with minimal stress on the membranes.

AS dates to the early 1900’s and depends on the digestion of biosolids under precision-controlled process conditions. AS requires multiple tanks with concentrated microorganisms and aerobic conditions achieved by precision oxygen infusion and control, to digest the wastewater organics, remove nutrients and achieve the required effluent quality. AS systems with multiple continuous-flow reactors and separate clarifiers are also referred to as sequential batch reactor (SBR) systems. The typical AS system requires a great deal of electrical power and space, near constant on-site supervision and testing, additional chemical treatments, and much more mechanical movement, yet it produces minimally qualified effluent.

Benefits derived from our systems include:

- Uses approximately 50% of the Electrical Power of Activated Sludge (“AS”) process plants, 20% of the staffing of Activated Sludge (”AS”) process plants

- Removes of COD/BOD, solids and nutrients in a single unit

- Uses a low pressure membrane environment for higher performance, extended life and minimum fouling

- Requires less than half the footprint of typical Activated Sludge process plants

- Has no offensive odor

- Can incorporate a Microgrid Electrical Power system for backup protection

- Includes “Hardening” features to protect against EPM, storm, flood, fire and earthquake disruption risks and expense

- Elimination of sludge bulking and related system process upsets

- Best available Life Cycle Cost Performance of any plant in existence

High Efficiency Wastewater Treatment Stages

The GPBG-CES wastewater team can provide Design Build (DB), Design Build Operate (DBO), or Design, Build, Operate, and Transfer (DBOT) services for advanced municipal wastewater and industrial wastewater treatment, and wastewater reuse utilizing CCE’s patented technologies.

The GPBG-CES system is an optimized activated sludge process utilizing eductor aeration and elegant basin hydraulic dynamics to achieve very high oxygen transfer rates, which combined with membrane filtration, yields re-use quality effluent water.

This process incorporates the current best engineering and industry practices in the safe, reliable, most cost-efficient management of domestic sewage and produces re-use quality discharge effluent water.

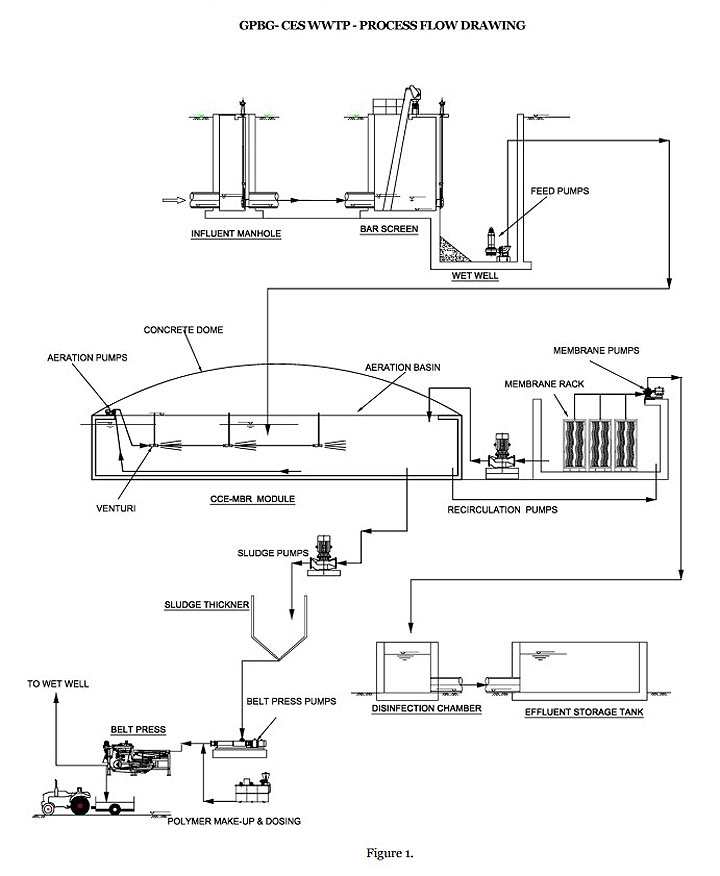

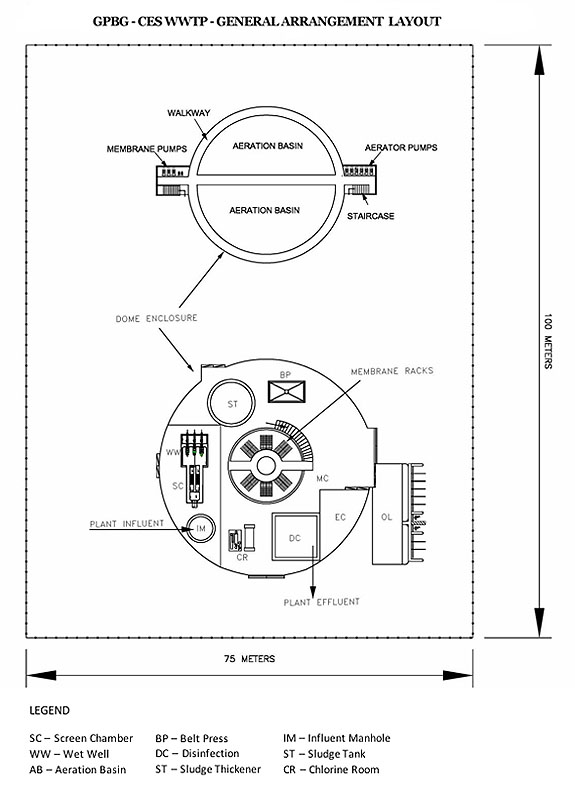

1. Raw sewage from the municipal collection system arrives at an influent manhole. The sewage then gravity flows into the mechanical bar screen structure, which traps and separates debris/trash.

2. Next, the sewage flows into the plant’s wet well (lift station). The wet well houses submersible pumps with lifting mechanisms which move the influent sewage to the aeration basin. The aeration basin with its innovative aeration and hydraulics avoids inefficient surface aerators that require costly maintenance cycles. Superior aeration along with an engineered hydrodynamic circulation optimizes oxygen transfer efficiency, BOD5 consumption, nutrient removal and sludge thickening. This is all achieved within a single activated sludge processing vessel.

3. Transfer pumps and system aerators re-circulate the aeration basin contents to achieve the required hydraulic pattern. The mixed liquor from the aeration basin is then gravity transferred to the membrane basin. This basin holds the hollow fiber membranes that provide the solid-liquid separation. The membranes are submerged in the mixed liquor and membrane pumps draw permeate from the mixed liquor through the hollow fiber membrane. The membrane bioreactor has an automatic cleaning system, a combination of air scrubbing, backwashing and chemical cleaning. The flow pattern through the membrane follows the outside-inside configuration and dead-end filtration. [This operation of the aeration basin bioreactor produces suspended solids concentrations in range of 8,000 – 10,000 mg/l and aeration basin loadings of 50 lbs BOD5/day-1000 ft3 of inventory, and membrane 0.1 micron pore size and 15 L/m2-hr flux.]

4. A recirculation pumping system provides a continuous flow between the aeration basin and membrane basin. Permeate from the membrane is dosed with chlorine from the gas chlorinator in the disinfection chamber. High quality effluent passes through a surge tank and is then ready for re-use.

5. Meantime, the sludge accumulated at the center of the aeration basin is transferred to the sludge thickener, where it is feed to a belt press for drying. Permeate from the belt press is recycled to the influent manhole – the dewatered sludge is sent for further treatment. The belt press is equipped with a hood which captures foul air and sends it to be deodorized and sanitized by an in-duct UV-light based hydroxyl radical generator to dry scrub the air.

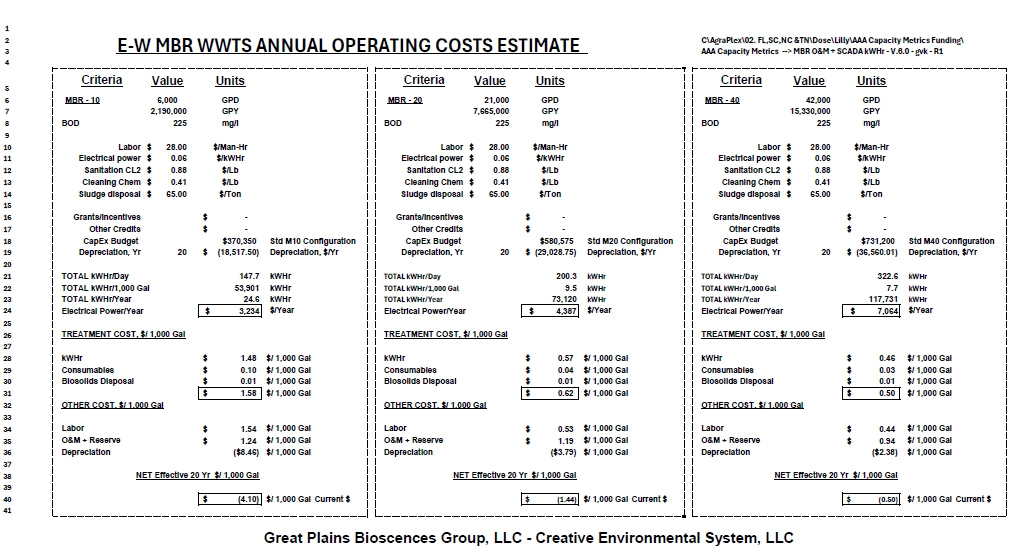

Operating Costs for MBR Plants

The following Operating Expense summaries are based on typical current costs. Including periodic membrane replacement expense, our MBR systems’ electrical power, labor, chemicals, and biosolids disposal efficiencies achieve 33%-to-50% lower OpEx operating costs compared to equivalent capacity Sequential Batch Reactor or Activated Sludge technology wastewater treatment systems.

The process consists, minimally, of two tanks or basins; a single (one) tank aeration basin for activated sludge, driven hydraulically in series with a second tank that is a membrane basin, whose effluent is finely filtered water and a separate mixed liquor recycle stream.

- With the introduction of membrane filtration, the aeration basin operates at a significantly high-activated microbe concentration and ably supported by an eductor based oxygenation system.

- There are no ancillary sub-systems and associated pumps, no clarifier required nor drive or traverse bridges. The site footprint is significantly smaller than a conventional plant with equivalent capacity through the elimination of unnecessary subsystems.

- The GPBG-CES WWTP process achieves significant energy savings (up to 50%) as the entire plant operates using two fluid pumps.

Atmospheric pressure, non-compressed air is aspirated into very fine bubbles in the recirculating flow of activated sludge. The recirculating flow is directed in a torroidal pattern down the aeration basin wall, across the bottom, up the center of the tank, and then radially outward back to the walls in the basic configuration.

In an optimal configuration, a dual torroidal pattern can be induced to create an upper and lower recirculation as illustrated in Figure 2a with the external recirculation loop, that drives the internal pattern, illustrated in Figure 2 b.

The upper zone is predominantly aerobic driving aerobic respiration cycles and the associated conversion of carbonaceous constituents from the influent wastewater as well as nitrification of the organic nitrogen and ammonia present. The lower zone is predominantly anoxic, driving de-nitrification reactions and thereby achieving nitrification and de-nitrification in a single vessel.

Surface aeration (by absorption of air into the water and the in-situ bulk

recirculation top-to-bottom of the torroidal cells) also occurs, as well as the aeration basin’s flow pattern, optimizing oxygen transfer rates and efficiencies. The aeration basin’s complete mix flow pattern precludes stagnant, “dead” flow zones.

Thus, accurate control of Dissolved Oxygen is efficiently achieved in the GPBG – CES WWTP in two ways:

1. Controlling variable-speed drive pumps by which increased air volumes are aspirated as the flow rate is increased, or Modulating valves on the aeration basin transfer pump(s) to achieve oxygen loading rates.

2. Oxygen Transfer Efficiency >28% without membranes or acid cleaning is achieved through synergy of the basin flow pattern and the mechanical dispersion of very _______ Clarification is achieved by Membrane filtration.