Operating an Environ-Works modular/package plant

First, the site has to be prepared, with collection and discharge piping, and power service in place. The site needs to be graded flat with a surface/pad of minimum 6” compacted gravel or 4” of concrete. One side of the plant can be set into an 8’ hill if desired and backfilled. Access around at least three sides is necessary for service vehicles (5000 sf – 15,000 sf, depending on plant size).

The modular plant comes trucked to the site and is lifted into place with a crane. Commissioning requires installation inspection; testing of instrumentation and control circuits; testing of data collection and communication components; checking programming and checking for system leaks; and introducing the microbes and nutrients. This process incorporates the current best engineering and industry practices in the safe, reliable, most cost-efficient management of domestic sewage and produces re-use quality discharge effluent water.

The wastewater stream is started from the holding tank(s) and the aerobic cycle begins.

System flow rates, tank levels, process activities, status and discharge water quality are continuously monitored and recorded. Out of tolerance conditions initiate alerts and/or alarms to initiate action.

System flow rates, tank levels, process activities, status and discharge water quality are continuously monitored and recorded. Out of tolerance conditions initiate alerts and/or alarms to initiate action.

System controls are backed up and will initiate a shutdown automatically if necessary. The operation and status of chief components are reported via a SCADA standard system with a computer and cell phone interface. In most cases, there is no required onsite operator, just a monitoring individual, who generally also maintains the system.

Periodically, depending on the loads and capacity of the units, solids are removed for disposal at a landfill or used for soil augmentation.

Because of the thoroughness of the treatment, the resulting biosolids are a fraction of the amount produced in an Activated Sludge system. On a schedule, membrane racks go through a more extensive cleaning, which enhances their effectiveness and longevity.

With the heavy-duty design of the plant, and commercial grade of all components (pumps, sensors, testing devices, switches, etc.), a plant is expected to last 50 – 100 years. Occasional pump replacement is to be expected, but the majority of components last years. With redundant components, SCADA-based performance monitoring, and scheduled maintenance programs, our wastewater treatment plants are as efficient, self-sufficient, and trouble-free as possible.

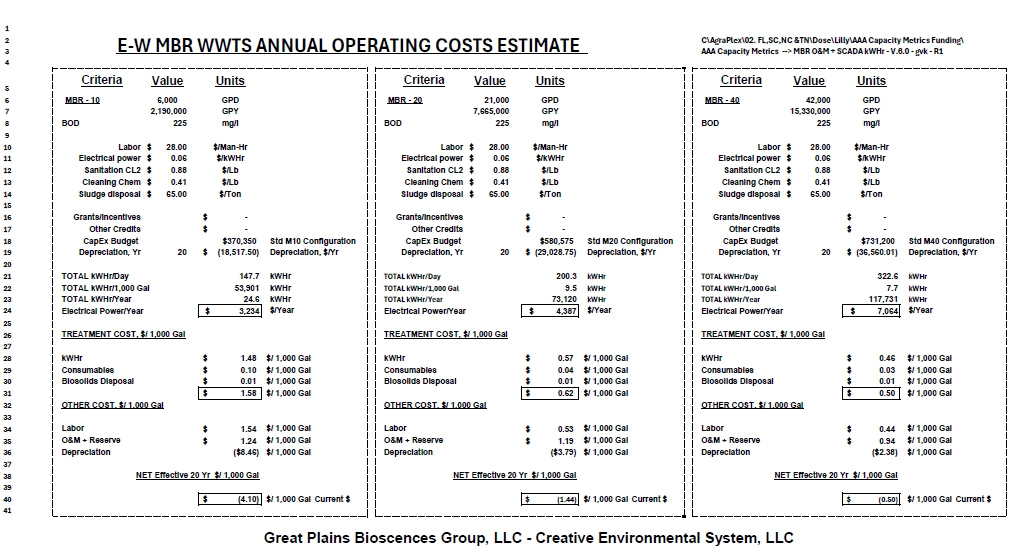

The following Operating Expense summaries are based on typical current costs. Including periodic membrane replacement expense, our MBR systems’ electrical power, labor, chemicals, and biosolids disposal efficiencies achieve 33%-to-50% lower OpEx operating costs compared to equivalent capacity Sequential Batch Reactor or Activated Sludge technology wastewater treatment systems.

Major Benefits

Asheville, NC

Sales: Phone 828.460.9529

[email protected]

Corporate: 828.506.2087

[email protected]

© Copyright 2024 Environ-Works, LLC. All Rights Reserved. | Design by e-outbox