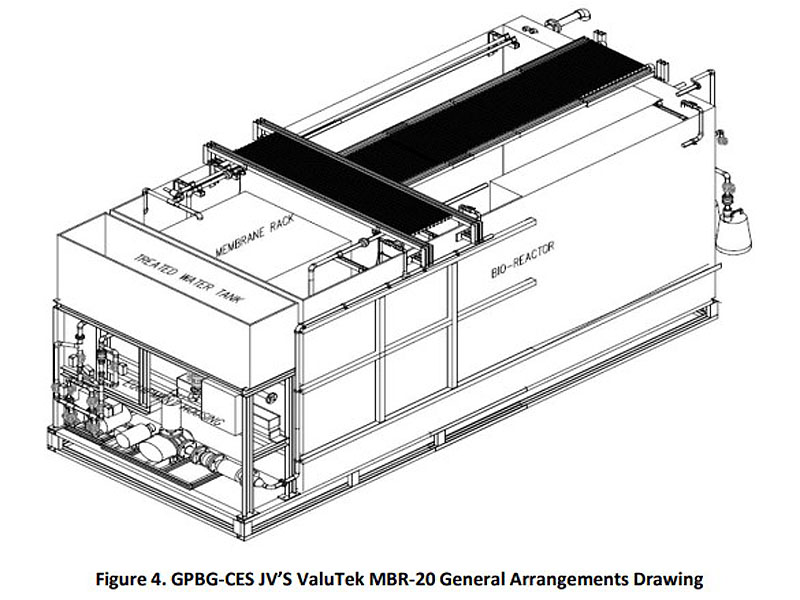

Package or Modular plants are the ideal answer for smaller, stranded communities. They save land for improvements by not requiring septic fields.

Plants can be placed close to clusters of homes, shortening collection lines and eliminating the biggest issue with present day sewage treatment – broken, leaking pipes. And they are innocuous – compact units that can be partially buried at the bottom of a slope.

Plus, they erase one of the biggest impediments to residential and resort development – wastewater treatment for a concentration of people. Package plants can also be configured to handle brewery pre-treatment and industrial waste of all kinds.

We offer three standard sizes (but modifications are available):

Plants can all be modified to incorporate larger holding tanks, in case of seasonal surges; stainless steel tanks for almost unlimited life; and backup microgrid power systems, which is highly recommended – photovoltaic, generator, or wind turbine. Multiple plants can be utilized in larger developments to handle much larger numbers of people.

All plants come standard with these features:

Major Benefits:

Typical MBR System Installation Requirements:

Asheville, NC

Sales: Phone 828.460.9529

[email protected]

Corporate: 828.506.2087

[email protected]

© Copyright 2024 Environ-Works, LLC. All Rights Reserved. | Design by e-outbox